Build Faster, Build Better: Our Advanced Concrete Solutions

- We specialize in crafting custom concrete formulations meticulously tailored to meet the exacting demands of each structure, ensuring unparalleled strength and performance.

- At our cutting-edge fully automated batching plants, we meticulously produce Ready-Mix Concrete (RMC) with precision. Our advanced quality control systems oversee every aspect of the production process, ensuring excellence from start to finish.

- Utilizing our proficiency in dispatch and meticulous tracking systems, we guarantee punctual delivery of every truckload, fulfilling each order promptly to meet the exacting demands of our valued customers.

- Our comprehensive range of Ready-Mix Concrete (RMC) extends from Grade M7.5 to M60 and beyond, precisely tailored to match the specific structural requirements of each project.

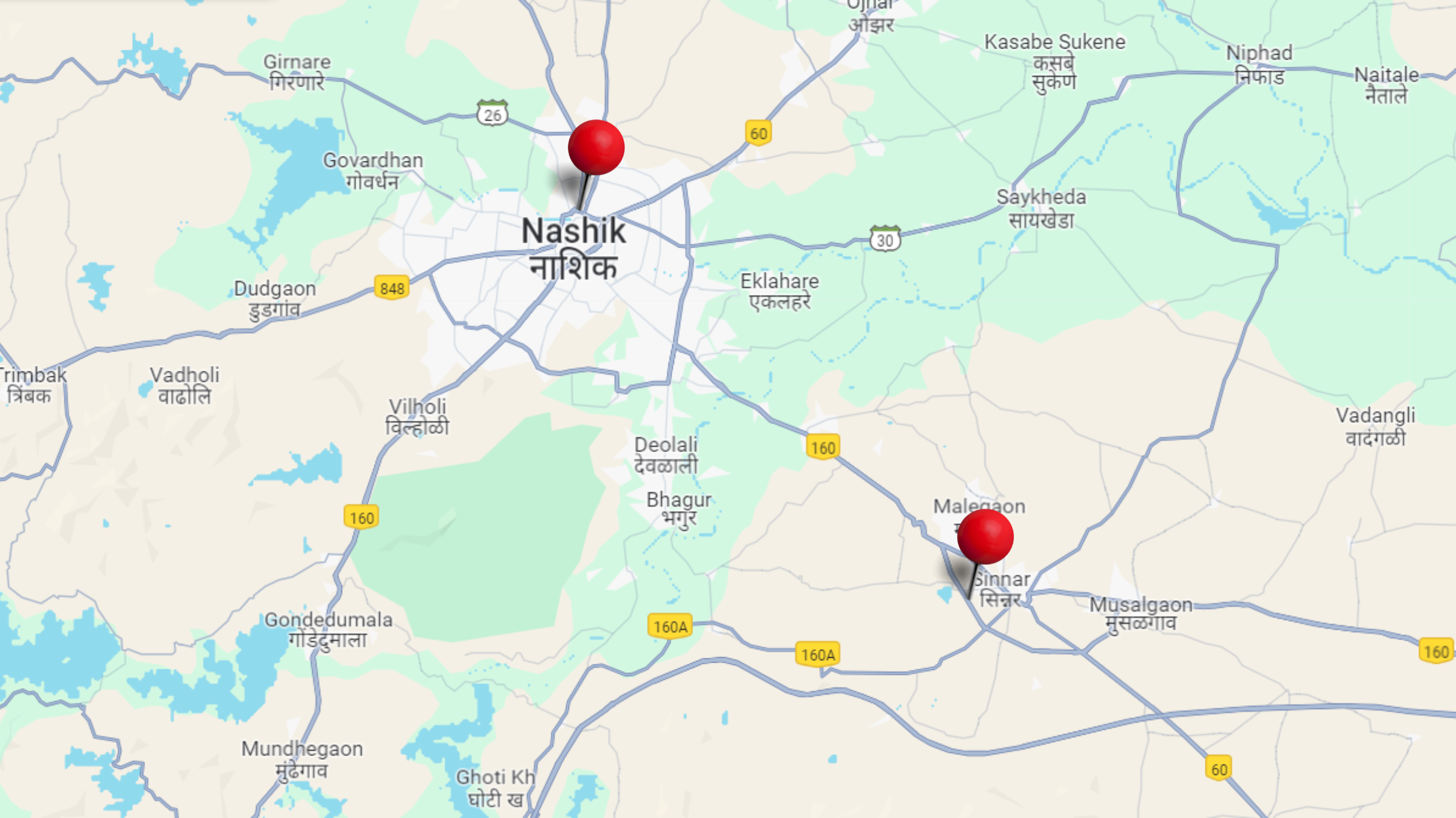

- Delivering top-quality Ready-Mix Concrete (RMC) throughout Nashik, our strategically located plants in Sinnar and Nashik ensure swift and efficient distribution, catering to diverse construction needs with precision and reliability.

Our Special Products

ExpressCon

- Speeds Up Construction & Boosts Durability.

- This high-strength concrete allows faster construction and earlier building use.

- It’s made with special blends and advanced additives for a denser, more durable structure.

| Key Feature | Application |

|---|---|

| Accelerates critical sections of construction process | Pavement & Trafficked roads |

| Reduced labour and equipment working hrs | Pre-stressed concrete structures |

| Increased productivity due to quicker removal of frameworks | Precast applications: Beams, Panel & Specific elements |

| Structure can put into intended use earlier Tunnel & Subways | Tunnel & Subways |

| Cost effective solution | Concrete casting using Aluform systems. |

| Temporary water control structures | |

| Climbing & Gliding framework systems |

FlowCon

- Self-Compacting Concrete for Easier Work & Flawless Designs.

- FlowCon’s special formula makes it self-leveling and requires minimal compaction.

- Ideal for intricate designs, it fills voids for a smooth, flawless finish.

| Key Feature | Application |

|---|---|

| Excellent quality in terms of surface finish; no honey combs, voids, etc. and hence, enhanced long-term durability. | Retaining walls, raft, footings and pile foundations |

| Safer working environment due to less labour required on site during placement of concrete | Repair, restoration and renewal of RCC structures. |

| Environmental friendly as, minimum vibration mitigates noise pollution | RCC members with heavy and congested reinforcement |

| Better progress and speedy completion of project. | RCC elements of intricate and complicated shape and design |

FiberCon

- Tougher Concrete for Demanding Projects

- FibreCon’s reinforced with fibers (polyester, etc.) to resist cracking and improve strength.

- Perfect for heavy-duty projects like Trimix floors, it delivers lasting performance.

| Key Feature | Application | |

|---|---|---|

| Reduced plastic settlement and plastic shrinkage cracking | Concrete roads, beams and precast concrete girders which require additional flexural strength. | |

| Increased durability as it improves toughness, flexural, fatigue and abrasion resistance | Slab on grade: All types of concrete pavements, industrial floors, airport taxiways, hangers etc | |

| Increased homogeneity and reduced bleeding | Heavy traffic wearing surfaces such as warehouses, container yards, railway platforms etc. | |

| Superior durability with high flexural and fatigue strength |

|

ThermoCon

- Cool Concrete for Faster Construction.

- This unique blend uses chilled water to control temperature, reducing cracks and drying time.

- Perfect for critical projects, ThermoCon speeds up construction and delivers superior quality.

| Key Feature | Application |

|---|---|

| Controls the temperature differential between the core and surface of the concrete, thereby mitigating thermal tensile cracks. | Bridge Foundation & Bridge Piers |

| Reduced plastic shrinkage cracks in fresh concrete | Large retaining walls |

| Rapid loss of slump and drying of fresh concrete is controlled | Mass raft foundations and deep beams |

| Controlled early setting and stiffening of concrete | Hydro-electric & power projects, mass concrete works in damss |

LightCon

- LightCon is a special concrete, produced by using composite material consisting of Portland cement, aggregates, porous fillers, and modifying agents. Its density varies from 800 to 1500kg/m3.

- Made with special fillers, LightCon offers superior insulation (thermal & acoustic) at a lighter weight. Ideal for roofs, floors, and electrical applications where energy savings and sound control matter.

| Key Feature | Application |

|---|---|

| Reduction in structural dead load | Roofs and floors as an insulating material |

| Excellent fire resistance properties | Low strength filler material for variety of applications |

| Ease of handling & transportation. Construction of partition walls | Construction of partition walls |

| Free flowing – spreads to fill all voids, thus enabling faster work | Low strength filler material for variety of applications |

MegaCon

- Megacon is a special concrete which gives high strength for concrete generally M60 above.

- It is produced by using high cementitious and specially formulated micro fines with high quality admixtures.

| Key Feature | Application |

|---|---|

| High early strength allowing early stripping times and speedy construction | RCC columns and beams in high rise buildings |

| Supports high-rise constructions. | columns, beams and girders for mega-urban infrastructure projects |

| Jumbo Strength and Dense Concrete | Marine structures |

| Increased floor space availability. | Precast structural elements. |

EcoCon

- EcoCon is a special concrete which gives high durable mix and low environmental impact.

- It is produced by using green products available in the industry waste which provides the structure a good shielding to protect from harmful environmental attack.

| Key Feature | Application |

|---|---|

| Durable & Sustainable. | Mass foundations. |

| Low heat of hydration. | Underground structures. |

| Continue strength gain upto lateral ages. | General industrial flooring. |

| Mitigate cracking. | Concrete pavements. |

| Mitigate cracking. | Reinforced and precast concrete elements. |